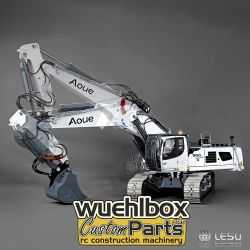

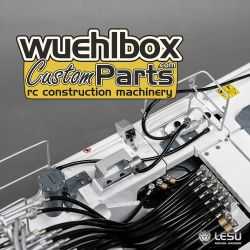

1. The entire machine is driven by hydraulic power, with 90% of the fixed oil circuit welded from pure copper, ensuring both a highly realistic appearance and the stability and sealing of the oil circuit system.

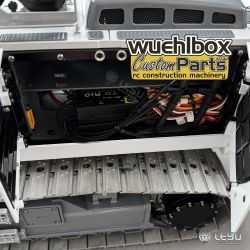

2. The hydraulic workstation uses a dual-pump, dual-power system, providing balanced power distribution, resulting in more coordinated, smooth, and linear movements. The oil tank features a visible large window and a visible hydraulic oil filter, making it easy to monitor the oil circuit system.

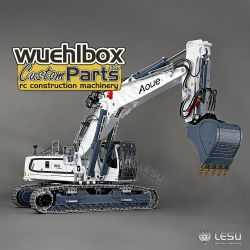

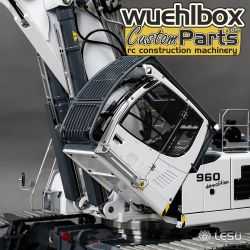

3. The machine adopts a modular design, with full lighting throughout. It is equipped with one warning light, two simulated GPS units, and nine doors that can be opened, offering more convenient operation.

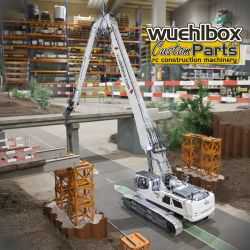

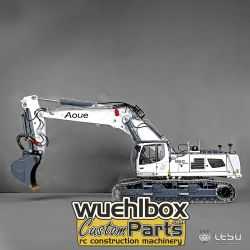

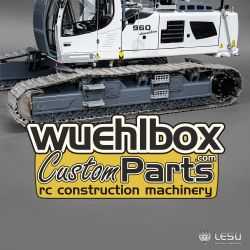

4. The machine consists of 95% metal parts, with an all-metal track and copper-material travel frame, and is equipped with steel counterweights to provide a stable and robust body for the demolition arm.

5. It features hydraulic power for both travel drive and rotation.

6. The machine is equipped with an adjustable-width,dual-hydraulic-cylinder-powered telescopic travel frame.

7. It has adjustable guide wheels, allowing for greater maneuverability.

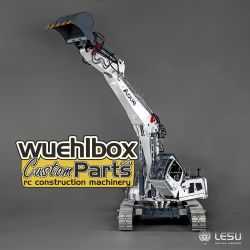

8. The rotation system integrates a seven-channel oil slip ring, offering high precision and excellent sealing, effectively preventing leaks, and providing stable hydraulic power to the chassis components.

9. This model introduces a newly designed simulated rotary support turntable, featuring easy installation, convenient maintenance, and space-saving installation.

10. It is equipped with a simulated stainless steel cab protective net, a hydraulically powered lifting cab, and an electronic display screen for real-time monitoring of electrical components.

11. The demolition arm is processed through full sheet metal welding, ensuring structural strength while maintaining balance between weight and the power system.

12. The boom is equipped with a 13-channel quick-release oil circuit system, and the electrical circuit uses a magnetic connection. It is equipped with a dem